PARADIM Highlight #105—External User Project (2025)

Serena Eley (U. Washington) and David A. Muller (Cornell U.)

Recently, iron germanium (FeGe) has become a testbed for a variety of magnetic phenomena. These include the ability to host skyrmions and antiskyrmions—nanoscale whirlpools of magnetic moments that could serve as information carriers. Here users of PARADIM developed a process to tune the disorder in epitaxial FeGe films in order to facilitate the coexistence of these magnetic whirlpools of opposite types.

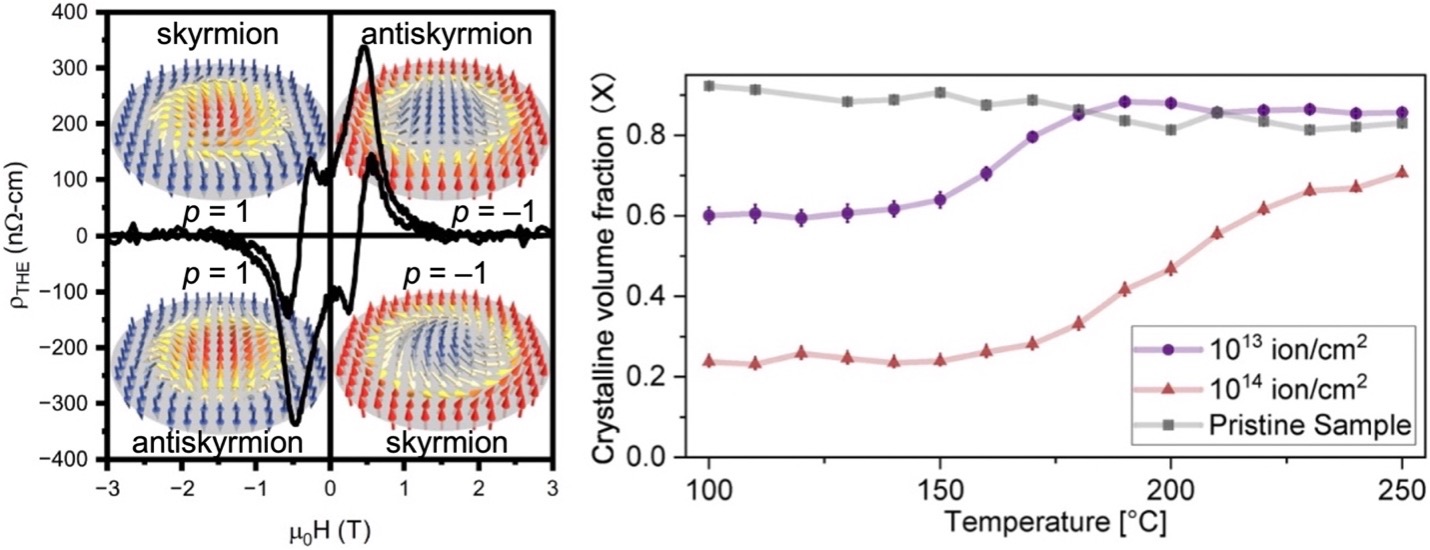

Figure 1: (left) Magnetic field-dependent topological Hall resistivity of FeGe film irradiated at 1013 ions/cm2 at 100 K. Each quadrant is labeled with the corresponding topological spin texture type and polarization associated with the peak or dip. (right) Temperature-dependent effective crystalline volume fraction X for the irradiated FeGe films during annealing.

First FeGe thin films were grown using PARADIM’s signature molecular-beam epitaxy system to the user’s specifications. After initial characterization, the samples were irradiated at Sandia National Laboratories, creating amorphized regions, forming a crystalline-amorphous composite that may host the skyrmions and antiskyrmions. Annealing at moderate temperatures recrystallizes the films and by carefully monitoring the heating-induced changes allows for finetuning the volume ratio of the crystalline-amorphous composite. Lastly, electron microscopy characterization was performed at the PARADIM’s Electron Microscopy Facility including support by a Kavli-PARADIM Fellowship.

Disordered iron germanium (FeGe) has recently garnered interest as a testbed for a variety of magnetic phenomena as well as for use in magnetic memory and logic applications. This is partially owing to its ability to host skyrmions and antiskyrmions—nanoscale whirlpools of magnetic moments that could serve as information carriers in spintronic devices. A tunable skyrmion–antiskyrmion system may be created through precise control of the defect landscape in B20-phase FeGe, motivating the development of methods to systematically tune disorder in this material and understand the ensuing structural properties.

The presented works investigate a route for modifying magnetic properties in FeGe. In particular, epitaxial B20-phase FeGe films were irradiated with 2.8 MeV Au4+ ions, which creates a dispersion of amorphized regions that may preferentially host antiskyrmions at densities controlled by the irradiation fluence. To further tune the disorder landscape, a systematic electron diffraction study with in situ annealing was conducted, demonstrating the ability to recrystallize controllable fractions of the material at temperatures ranging from ∼150 to 250 °C. The crystallization kinetics are described using the Johnson–Mehl–Avrami–Kolmogorov model, finding that the growth of crystalline grains is consistent with diffusion-controlled one-to-two dimensional growth with a decreasing nucleation rate.

A process was developed to tune disorder in epitaxial B20-phase FeGe films, which may be useful for controlling magnetic phenomena in this and other B20-phase materials. For example, irradiating the films creates amorphized regions, and the resulting crystalline-amorphous composite may host skyrmions and antiskyrmions. Annealing progressively recrystallizes the ion-beam-modified films. By monitoring the heating-induced changes in the crystalline structure through in situ SAED, the researchers determined that as the temperature increases, the crystalline volume fraction is first constant, then sharply increases, before plateauing.

It was also found that the temperature at which the crystalline volume fraction sharply increases depends on initial structural conditions and that the mostly amorphized FeGe from high fluence irradiation does not fully recrystallize at temperatures up to 250 °C within the investigated duration of the annealing process (104 min total, 3 min at 250 °C).

The primary phase in both recrystallized samples remains as the B20-phase. Finally, by applying both JMAK models, it was determined that the nucleation rate in both samples decreases during recrystallization, which suggests the formation of larger grains with fewer grain boundaries. Further studies are warranted—namely, LTEM, XMCD, or neutron scattering—to definitively identify the magnetic structures that emerge in irradiated FeGe and annealed FeGe. The results can also contribute to establishing structure–property relationships in the FeGe system for spintronic applications.

MBE growth equipment with a flexible arrangement of sources, and custom high-speed, high dynamic range electron detectors on the high-brightness field emission electron microscopes.

The work was initiated by Prof. Serena Eley at the University of Washington and included work at PARADIM’s Thin Film Facility, Sandia National Laboratories, and final characterization at the PARADIM Electron Microscopy Facility.

- M.B. Venuti, X.S. Zhang, E.J. Lang, S.J. Addamane, H. Paik, P. Allen, P. Sharma, D.A. Muller, K. Hattar, T.-M. Lu, and S. Eley, "Inducing a Tunable Skyrmion-Antiskyrmion System through Ion Beam Modification of FeGe Films," npj Spintronics 2, 16 (2024). DOI: 10.1038/s44306-024-00013-8

- J. Liu, R. Schoell, X.S. Zhang, H. Yang, M.B. Venuti, H. Paik, D.A. Muller, T.-M. Lu, K. Hattar, and S. Eley, "Structural Properties and Recrystallization Effects in Ion Beam Modified B20-Type FeGe Films," APL Mater. 13, 011112 (2025). DOI: 10.1063/5.0237131

- This material is based upon work supported by the National Science Foundation under grants DMR-1905909 and DMR-2330562 at the Colorado School of Mines and the University of Washington. This work also used synthesis and microscopy facilities at the Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM), which is supported by the National Science Foundation under Cooperative Agreement no. DMR-2039380. Part of this work was performed at the Center for Integrated Nanotechnologies (CINT), a DOE Office of Science User Facility, and Sandia National Laboratories, managed and operated by NTESS, LLC, a wholly owned subsidiary of Honeywell International, Inc., for the U.S. DOE’s National Nuclear Security Administration. The views expressed in the article do not necessarily represent the views of the U.S. DOE or the United States Government. M.B.V. thanks David Lidsky (Sandia National Labs) for assistance in using cleanroom instrumentation at CINT.

- This work also made use of synthesis and microscopy facilities at the Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM), which is supported by the National Science Foundation under Cooperative Agreement No. DMR-2039380. Part of this work was performed at the Center for Integrated Nanotechnologies, a DOE Office of Science User Facility, and Sandia National Laboratories, managed and operated by NTESS, LLC, a wholly owned subsidiary of Honeywell International, Inc., for the U.S. DOE’s National Nuclear Security Administration. The views expressed in the article do not necessarily represent the views of the U.S. DOE or the United States Government.

Data Availability: Data associated with this work are made available via DOI: 10.17632/xd8s497nsz.3