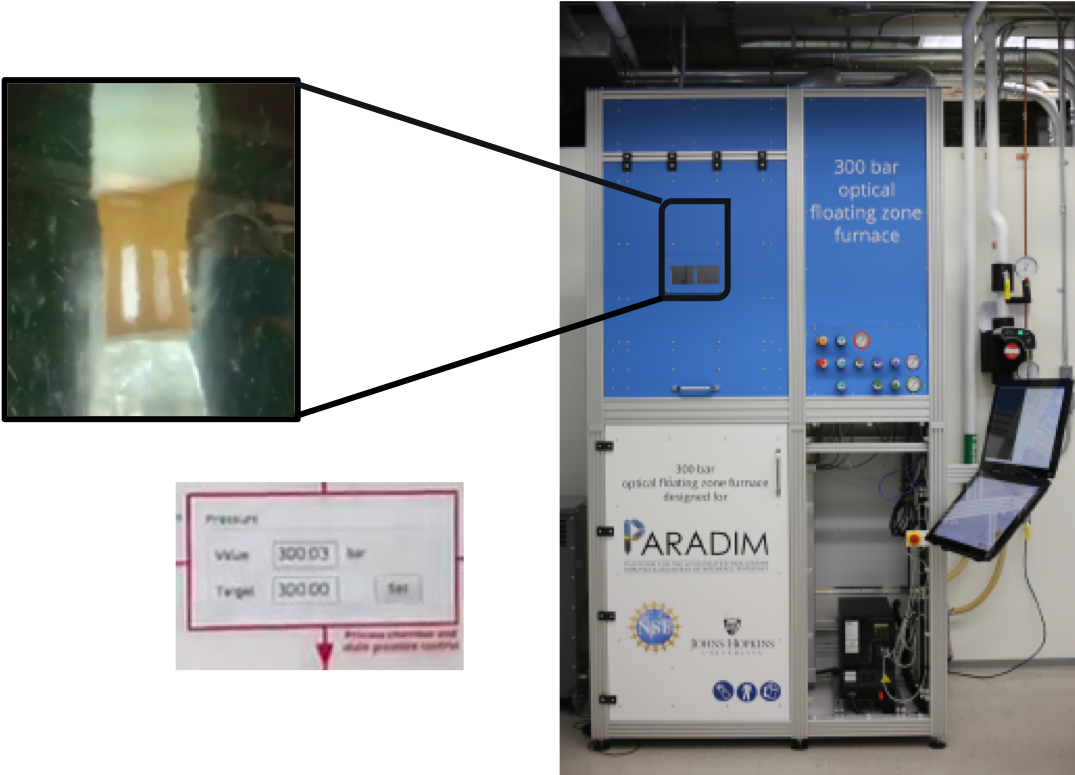

A new world record for highest pressure of a floating zone crystal growth, at 300 atmospheres, twice the previous record, was achieved by PARADIM staff in the United States in collaboration with our industry partner SciDre. This work was done at Johns Hopkins University by Tyrel M. McQueen and W. Adam Phelan.

|

| Figure 1: PARADIM's 300 bar Optical floating zone furnace, melt zone sample and controller pressure read out |

Under these conditions, most gases are “supercritical,” i.e., there is no distinction between the liquid and gas phases, and the fluid has a density of 1/3 to 1/2 that of the cryogenic liquid; this is a new frontier in the synthesis (and discovery!) of materials for the next generation of electronics.

The development of this technology enables the improvement of existing electronic materials and the discovery of new electronic materials that have never before been made in a form suitable for use in device applications.

It was made possible by the NSF MIP’s commitment to significant investment in unique infrastructure and capabilities and is available free to U.S.A. users through 2-page proposals.

Technical details:

The science and capabilities of crystal growth have historically lagged behind polycrystalline synthesis strategies., and this is no exception. With the development of 300 atm floating zone growth, we are now positioned as the only facility in the world capable of utilizing the continuously tunable properties of supercritical fluids – which can dissolve chemicals like a liquid but flows and expands to fill its container like a gas – in the production of high temperature melting functional materials.

We engaged SciDre (press release here: http://scidre.de/index.php?id=116 ) to do the engineering development of an apparatus suitable for these experiments. Initial testing at SciDre demonstrated a holding pressure of 450 atm when cold, and 300 atm when hot.

However, due to the large heat and mass flows that are possible in supercritical fluids, it was not until this unique instrument was installed at PARADIM@JHU and undergoing acceptance testing that a stabilized molten zone and demonstrated crystal growth under these conditions was achieved – due to the expertise of PARADIM staff in the floating zone method.

The entire project was only made possible by the significant investment in infrastructure provided by the MIP program.

Return to: In-house Research Highlights