PARADIM Highlight #40—External User Project (2021)

Peter G. Khalifah, Brookhaven National Lab & Stony Brook University

The optical floating zone (OFZ) method is one of the most versatile and important techniques for growing large single crystals needed for the study of emerging functional materials, such as those used exhibiting superconductivity, ferroelectricity, and energy conversion and storage.

|

|

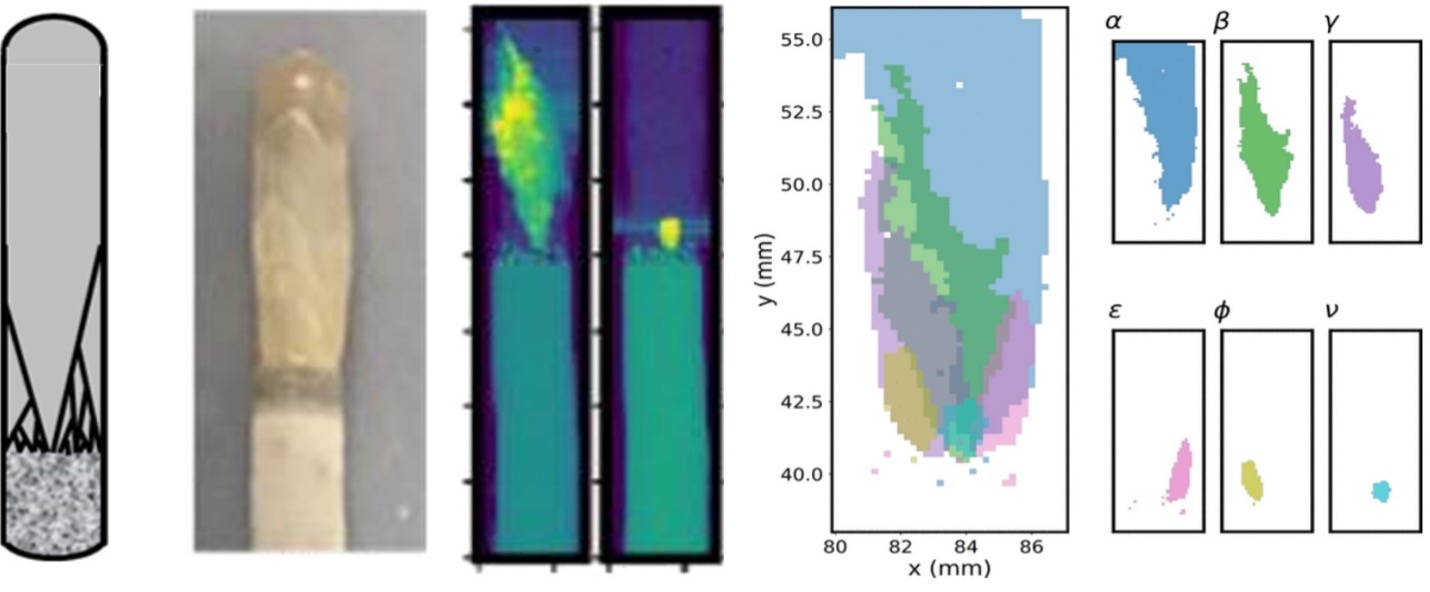

Figure:(from left: schematic of grain nucleation and growth during the OFZ process, photograph of TiO2 multicrystal grain from early in the seeding process, raw consecutive synchrotron grain maps, and reconstructed maps of grains and their evolution during OFZ growth, demonstrating the ability to directly visualize the OFZ seeding and growth process and dynamics. |

Using a TiO2 polycrystal-to-single-crystal boule grown at PARADIM’s bulk crystal facility, Peter Khalifah and his team in the GENESIS EFRC demonstrated that high-energy synchrotron X-rays can non-destructively probe large OFZ boules to determine position, shape, orientation, and quality of individual crystals grains within the boule. While multiple grains grew large, one single winning grain (blue in the reconstructed map, α) grew faster than the other grains, terminating their growths while expanding to encompass the entire diameter of the top of the crystal growth boule.

The information provides direct access to grain formation and growth dynamics and will lead to improved models of crystal growth that accelerate materials development.

What Has Been Achieved:

An automated and rapid method for nondestructive mapping of crystal grains utilizing high energy synchrotron X-rays was developed. The approach was designed for eventual application to in situ float-zone crystal growth experiments at an X-ray synchrotron source. The approach applies a statistical filter to polycrystalline diffraction patterns on two-dimensional (2D) detectors to rapidly determine the degree of powder quality of the signal. When larger crystals emerge in the growth, their position, size, and shape can be tracked using an automated blob-tracking algorithm that follows individual Bragg peaks as a function of position in a grid scan, even when multiple crystals are contributing spots to diffraction images. This method is found to be robust as the same crystal shape can be independently reconstructed using different sets of Bragg reflections. Image segmentation methods are then used to map out the polycrystalline grains. We also note that other information about crystal quality, such as mosaicity or strain state, may be inferred and mapped from the intensity variation of the Bragg peaks at different locations within the sample. The methods have been tested on a TiO2 polycrystal-to-single-crystal boule grown in the PARADIM laser diode float-zone furnace.

Importance of the Achievement:

Synchrotron X-ray diffraction mapping studies have been used to non-destructively follow the crystal selection process by which one grain grows to fill the entire diameter of the OFZ crystal growth boule. This work is enabled by novel computational data science methods and will enable future developments in models for growth of novel materials by the OFZ technique.

Unique Feature(s) of the MIP that Enabled this Achievement:

This work was enabled by the floating zone suite within the Bulk Crystal Growth facility, which enabled growth of TiO2 single crystals in the tilting laser diode floating zone furnace.

Publication:

C.J. Wright, E. Dooryhée, L.A. Pressley, W.A. Phelan, P.G. Khalifah, and S.J.L. Billinge, "Toward In Situ Synchrotron Mapping of Crystal Selection Processes during Crystal Growth," Chem. Mater. 33, 3359–3367 (2021).

Data Reference:

Growth data of TiO2 single crystals are publicly available at https://data.paradim.org/188.

Acknowledgement:

The authors thank Tyrel McQueen (JHU), Jonathan Denney (SBU), and Yusu Wang (SBU) for helpful discussions. This work was supported as part of GENESIS: A Next Generation Synthesis Center, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences under Award No. DE-SC0019212. Use of beamline 28-ID-1 at the National Synchrotron Light Source-II, Brookhaven National Laboratory, was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-SC0012704. This material is based upon work (crystal growth through a user proposal) supported by the National Science Foundation (Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM)) under Cooperative Agreement No. DMR-1539918.