PARADIM Highlight #47—External User Project (2021)

Jian Shi (Rensselaer Polytechnic Institute) and Jeehwan Kim (Massachusetts Institute of Technology)

Important applications like ultrashort pulsed lasers, sensors, laser amplifiers, and digital optical information processing, depend on materials with nonlinear optical properties—that is the material’s nonlinear interaction with electromagnetic waves, e.g., light.

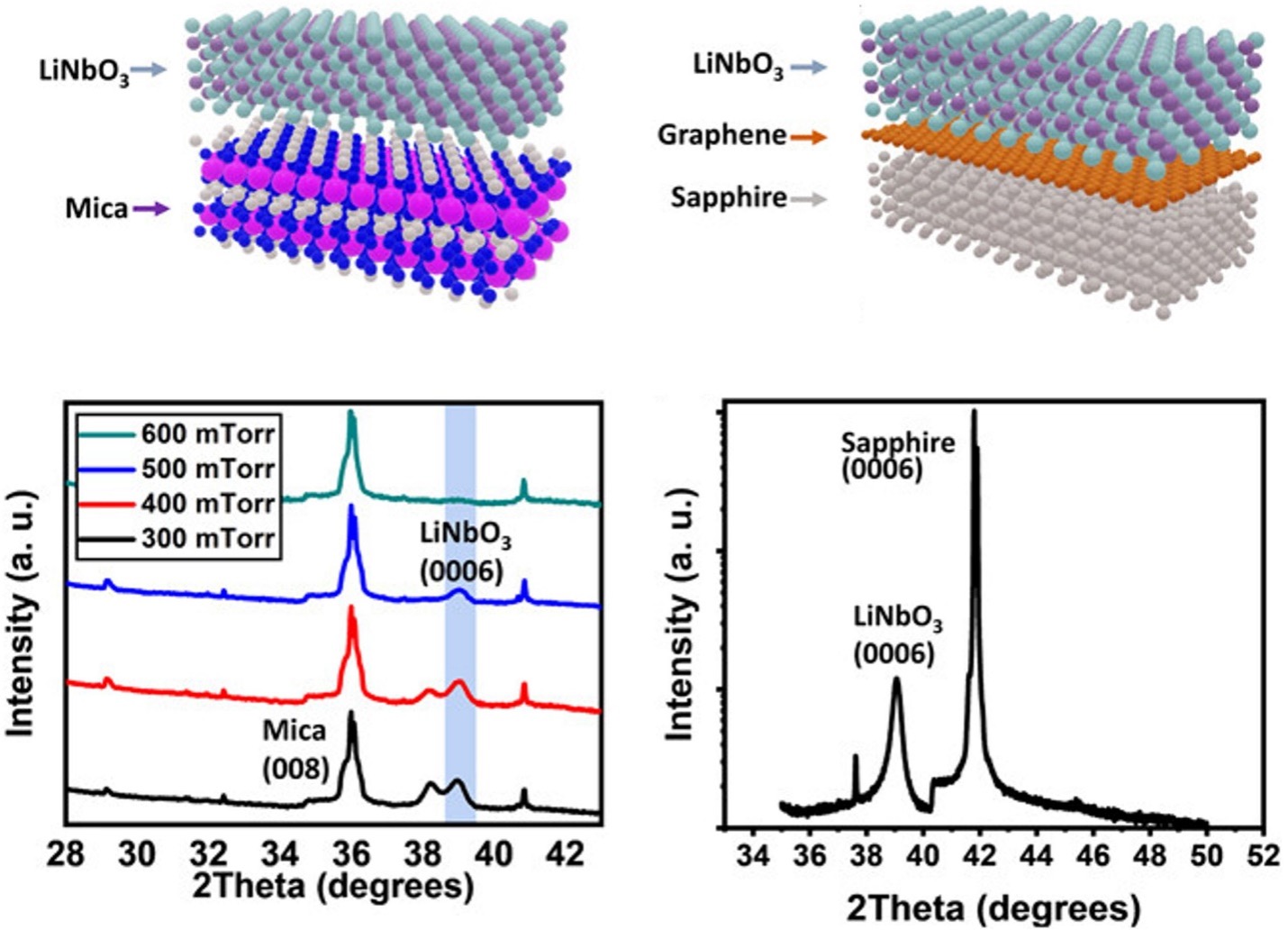

Figure 1: Schematics of the proposed heterostructures using mica or graphene as immediate substrates. (bottom, left) XRD spectra of van der Waals epitaxial LiNbO3 films on mica (001) grown at 550 °C with the oxygen pressure ranging from 300 to 600 mTorr. (bottom, right) XRD spectrum of a remote epitaxial LiNbO3 film on graphene/sapphire, deposited at 550 °C in 500 mTorr oxygen.

One of the widely used materials for nonlinear optics is lithium niobate (LiNbO3) but growth in thin film form for use in photonic integrated circuits remains challenging. Enhancing the quality of thin films may enable the reduction of device dimensions as well as the operating voltage, making it easier to modulate electrical and optical properties.

One of the widely used materials for nonlinear optics is lithium niobate (LiNbO3) but growth in thin film form for use in photonic integrated circuits remains challenging. Enhancing the quality of thin films may enable the reduction of device dimensions as well as the operating voltage, making it easier to modulate electrical and optical properties.

“The PARADIM user meeting provided a nice platform for users to get more connected and discuss collaborations.”

Jian Shi, RPI (July 2021)

Discussions among two PARADIM users and members of their research groups during one of PARADIM’s User Meetings made the teams join forces to realize epitaxial LiNbO3 thin films on various substrates via van der Waals and remote epitaxy. High-resolution structural characterization of the achieved films was enabled by access to PARADIM’s Electron Microscopy Facility.

In summary, we demonstrated the growth of epitaxial LiNbO3 film via van der Waals and remote epitaxy by pulsed laser deposition. Structural analysis has revealed the epitaxy relations and identified the presence of twin structures of LiNbO3 films in both LiNbO3/mica and LiNbO3/graphene/sapphire systems. In remote epitaxy, Raman spectroscopy has confirmed the existence of graphene after deposition suggesting the active role of graphene during the deposition process. The demonstration of the feasibility of van der Waals and remote epitaxy of LiNbO3 suggests a promising processing route toward the development of free-standing LiNbO3 films in the near future.

Providing a deeper understanding of remote epitaxy and its impact on film morphology is a crucial part to expanding the applicability of the technique to new classes of materials.

The annual PARADIM user meeting provides networking opportunities for the community of practitioners fostered at PARADIM. In the present case, two users with separate projects at PARADIM met and joined forces to move the field forward. PARADIM’s electron microscopy facility enabled high-resolution structural characterization of the synthesized thin film.

R. Jia, H.S. Kum, X. Sun, Y. Guo, B. Wang, P. Fang, J. Jiang, D. Gall, T.-M. Lu, M. Washington, J. Kim, and J. Shi, "Van der Waals Epitaxy and Remote Epitaxy of LiNbO3 Thin Films by Pulsed Laser Deposition," J. Vac. Science & Technol. A 39, 040405 (2021). DOI: https://doi.org/10.1116/6.0001109

This work was supported by the U.S. Air Force Office of Scientific Research under Grant No. FA9550-18-1-0116 (R.J. and J.S.) and the NYSTAR Focus Center at Rensselaer Polytechnic Institute (RPI) with Contract No. C150117 (X.S., T.-M.L, M.W., and J.S.). The authors declare no competing interests. This work is also supported by U.S. National Science Foundation under Award No. of 1712752 (D.G.). This paper is also supported by the U.S. National Science Foundation [Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM)] under Cooperative Agreement No. DMR-1539918 and made use of the Cornell Center for Materials Research (CCMR) Shared Facilities, which are supported through the NSF MRSEC Program (No. DMR-1719875).