PARADIM Highlight #70—User Collaboration (2023)

John T. Heron (U. of Michigan) and Tyrel M. McQueen (JHU)

X-ray micro-computed tomography (µCT) uses high-energy X-rays to non-destructively generate 3D representations of a material with micron/nanometer precision, taking advantage of various contrast mechanisms to enable the quantification of the types and number of inhomogeneities.

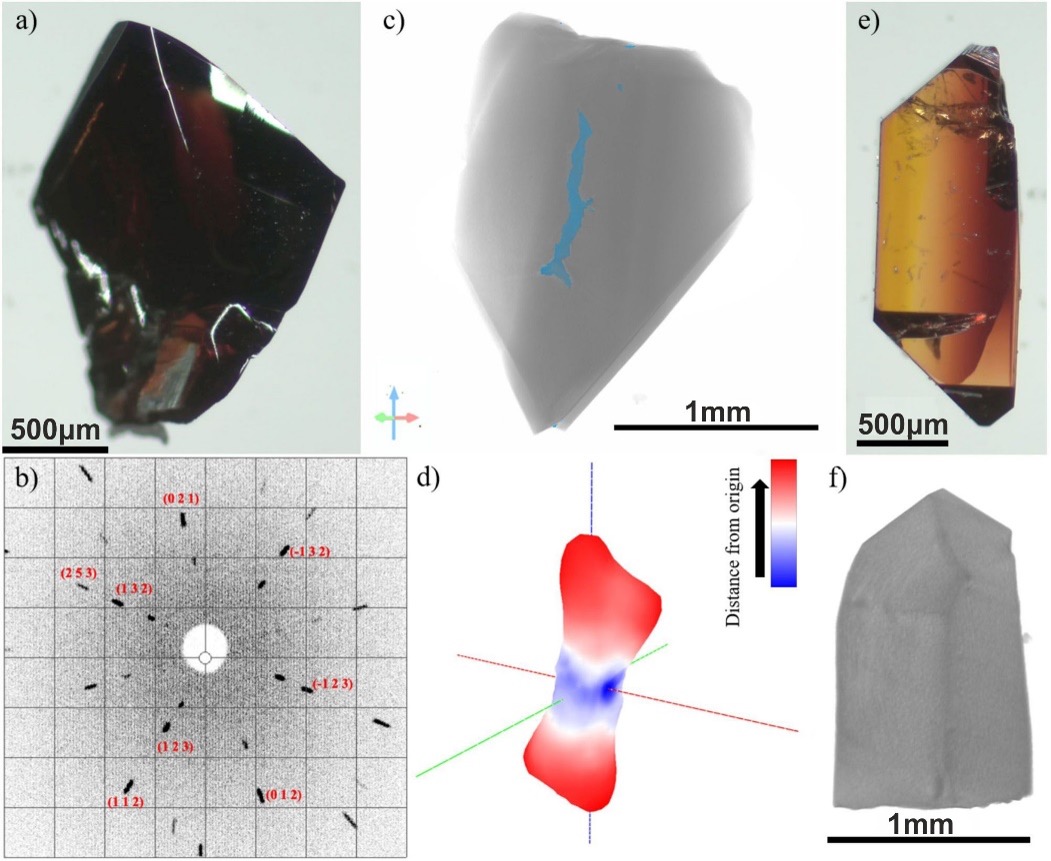

Figure 1: Voids in rutile germanium oxide, r-GeO2. a) A single crystal of rutile GeO2 grown using a flux with a cooling rate of 3 °C/h. b) Laue diffraction image of the crystal along the [011] direction. c) A representation of a crystal from the same batch as (a) generated from μCT data with voids present (highlighted blue). d) A 3D rose diagram of the star volume distribution of the voids. The data was aligned such that the void shows a preferential orientation parallel to the [011] direction of the crystal axis. The image is colored according to the distance from the origin. e) A different crystal of rutile GeO2 grown using a flux with a cooling rate of 0.5 °C/h. f) A rendering of a crystal from the same batch as in (e) showing no detectable voids.

Here, members of PARADIM’s in-house research team collaborated with external users and summer school participants on case studies of µCT informing materials design of electronic and quantum materials, benefitting the characterization of inclusions, twinning, and low-angle grain boundaries and optimizing crystal growth processes. The work discusses recent improvements in µCT instrumentation that enable elemental analysis and orientation to be obtained on crystalline samples, for example the PARADIM User-pioneered electronic materials rutile-GeO2 (depicted here).

The benefits of µCT as a non-destructive tool to analyze bulk samples should encourage the community to adapt this technology into everyday use for electronic and quantum materials discovery.

The presence of inclusions, twinning, and low-angle grain boundaries, demanded to exist by the third law of thermodynamics, drive the behavior of electronic and quantum materials. Identification and quantification of these structural complexities often requires destructive techniques but X-ray micro-computed tomography (µCT) uses high-energy X-rays to non-destructively generate 3D representations of a material with micron/nanometer precision, taking advantage of various contrast mechanisms to enable the quantification of the types and number of inhomogeneities. Here, members of PARADIM’s in-house research team collaborated with external users and summer school participants on case studies of µCT informing materials design of electronic and quantum materials, benefitting the characterization of inclusions, twinning, and low-angle grain boundaries and optimizing crystal growth processes. Recent improvements in µCT instrumentation that enable elemental analysis and orientation to be obtained on crystalline samples are also presented and discussed. The benefits of µCT as a non-destructive tool to analyze bulk samples should encourage the community to adapt this technology into everyday use for electronic and quantum materials discovery.

The demonstration that X-ray micro-computed tomography, traditionally used for structural materials, is able to provide chemically and optimization-relevant information on electronic and quantum materials – and to do so non-destructively -- opens new avenues to accelerating superior electronic materials synthesis and realization.

MIP signature tools were used in the creation of multiple materials used in the study, the MIPs cross-sharing agreements gave access to the needed µCT instrumentation, and the MIPs community of practitioners, both external users and summer school participants, were integral to success of the project.

L.A. Pressley, D. Edey, R. Hanna, S. Chae, J.T. Heron, M.A. Khan, and T.M. McQueen, "Informing Quantum Materials Discovery and Synthesis using X-ray Micro-Computed Tomography," npj Quantum Mater. 7, 121 (2022), DOI: 10.1038/s41535-022-00527-6.

This work was funded by the Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM), a National Science Foundation Materials Innovation Platform (NSF DMR-2039380). The UTCT facility is partially supported by NSF grant EAR-176245 with funding for the Zeiss Versa 620 funded by NSF MRI grant EAR-1919700. Access to the Bruker 1172 instrument was also possible via the Hopkins Extreme Materials Institute (HEMI). L.A.P., T.M.M., and M.A.K. would like to thank Navindra Keerthisinghe, Vicky Li, Trent Kyrk, and Olivia Vilella for their group participation in the high-pressure floating zone growth of YbMgGaO4 at the 2021 PARADIM Summer School at JHU. L.A.P. would like to thank Jessica Maisano for assistance with DCT data

Access to data associated with this work is provided through the PARADIM Data Collective: DOI 10.34863/sd37-3694.