PARADIM Highlight #72—External User Project (2023)

Kaveh Ahadi (NCSU), M.D. Williams (Clark Atlanta University), and D.A. Muller and D.G. Schlom (Cornell University).

Question: What do you get when you mix the bold vision of an Assistant Professor with a thin film community open to sharing emerging know-how?

Answer: A radical collaboration that has led to the world’s highest quality thin films of potassium tantalate KTaO3.

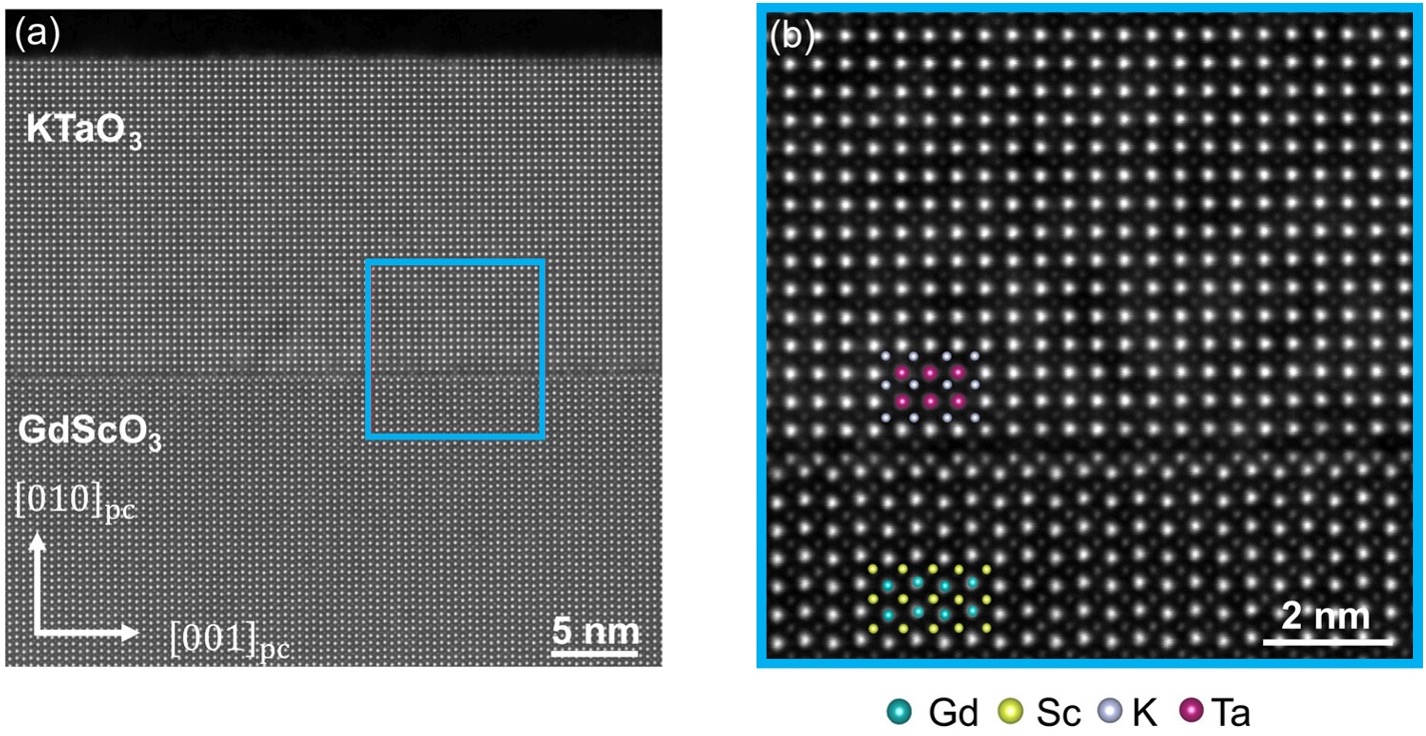

Figure 1: Atom resolution scanning transmission electron microscopy (STEM) image of a KTaO3 thin film on GdSc O3 and zoomed view on the interface with the substrate.

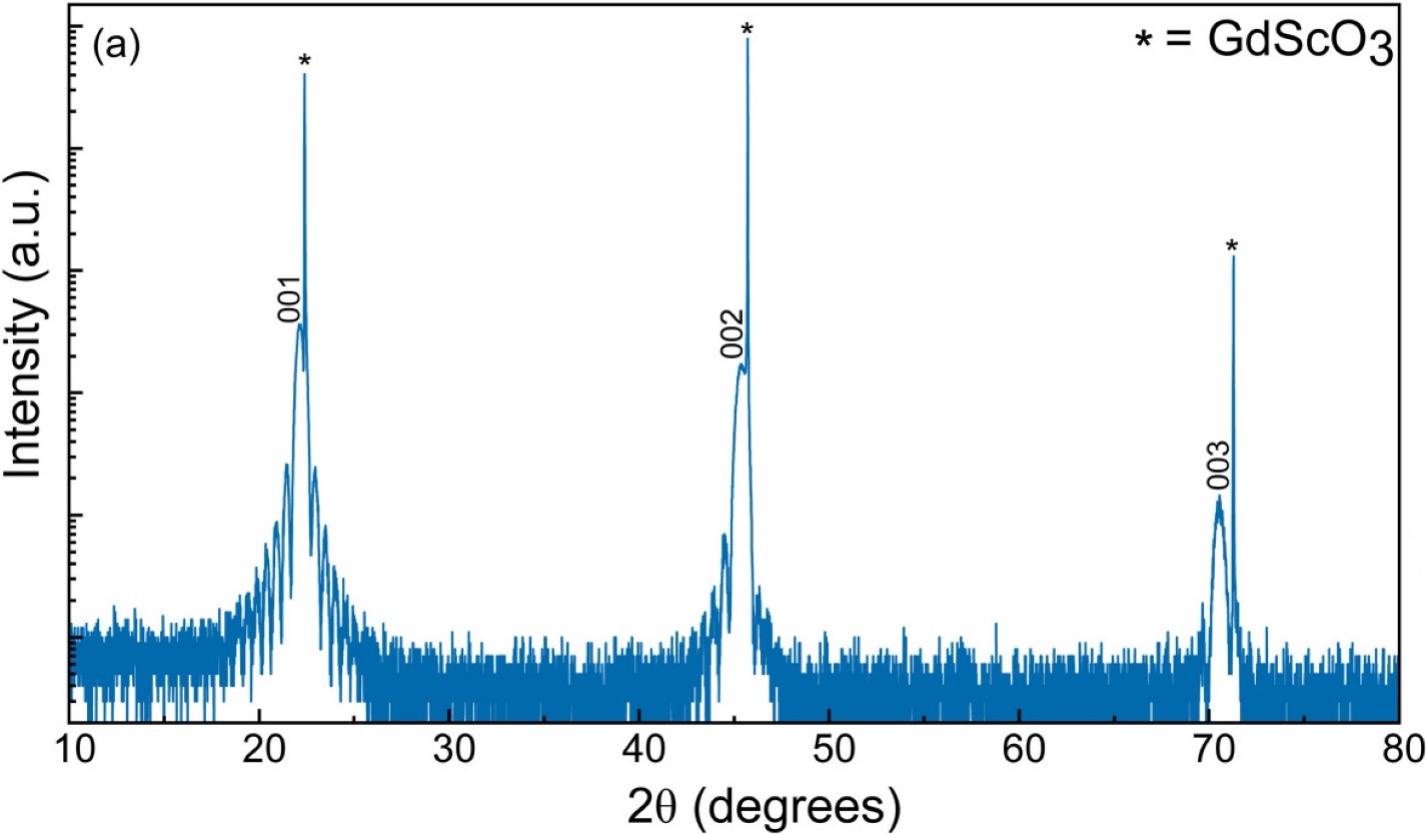

Figure 2: X-ray diffraction ) X-ray diffraction θ-2θ scan of a high-quality KTaO3 thin film showing 00l peaks and Laue fringes.

KTaO3 is an incipient ferroelectric, in which superconductivity emerges at low temperatures in electron-doped samples. The KTaO3 conduction band is derived from the Ta 5d states and shows highly anisotropic electronic transport. These opportunities invite the synthesis and intensive study of KTaO3-based thin films and heterostructures to understand and engineer these phenomena. Molecular-beam epitaxy (MBE) is an obvious method to tune the properties of KTaO3 by producing epitaxial heterostructures where strain, juxtaposed competing orders, or other approaches to modify the ground state can be imposed, but for technical reasons KTaO3 had never been grown by MBE.

Enter a bold user from NCSU who came to PARADIM’s Thin Film Facility on a mission to grow KTaO3 by MBE. At PARADIM, the successful growth of KTaO3 thin films was facilitated by two innovations from other PARADIM users: (1) suboxide MBE, used for GeO2, Ga2O3, SnTa2O6,… and (2) indium-alkali metal alloys that can be safely handled in ambient conditions and provide stable evaporation of the alkali metal as used for LiZnSb, Cs3Sb, NaxCoO2,... plus another PARADIM user interested in definitively testing (using SIMS) whether the resulting films were contaminated with indium, which they were not.

Strain-engineering is a powerful means to tune the polar, structural, and electronic instabilities of incipient ferroelectrics. KTaO3 is near a polar instability and shows anisotropic superconductivity in electron-doped samples. Here, we demonstrate growth of high-quality KTaO3 thin films by molecular-beam epitaxy. Tantalum was provided by either a suboxide source emanating a TaO2 flux from Ta2O5 contained in a conventional effusion cell or an electron-beam-heated tantalum source. Excess potassium and a combination of ozone and oxygen (10% O3 + 90% O2) were simultaneously supplied with the TaO2 (or tantalum) molecular beams to grow the KTaO3 films. Laue fringes suggest that the films are smooth with an abrupt film/substrate interface. Cross-sectional scanning transmission electron microscopy does not show any extended defects and confirms that the films have an atomically abrupt interface with the substrate. Atomic force microscopy reveals atomic steps at the surface of the grown films. Reciprocal space mapping demonstrates that the films, when sufficiently thin, are coherently strained to the SrTiO3 (001) and GdScO3 (110) substrates.

This publication marks the first time that KTaO3 films have been grown by MBE. The approach used overcame the technical challenges of (1) the low vapor pressure of tantalum (normally impossible in a stable MBE effusion cell due to the low vapor pressure of tantalum) and (2) the safety issues of safely handling potassium, which is highly flammable. The resulting films have the highest structural quality of any KTaO3 films ever grown judging from the narrowness of the x-ray diffraction rocking curves and rather featureless microstructure revealed by STEM.

On the technical side, PARADIM is where suboxide MBE was invented and previously demonstrated to work for GeO2, Ga2O3, SnTa2O6 and more oxides. Further, it is where alkali metals were safely contained in intermetallics with indium or tin in order to make LiZnSb, Cs3Sb, NaxCoO2, and other epitaxial films by MBE. On the social side, this publication involved the collaboration of three teams who met in PARADIM: (1) the NCSU team interested in growing KTaO3, (2) the Penn State team interested in growing KTaO3/KNbO3 superlattices by MBE (they are mentioned in the acknowledgements), and (3) the PARADIM PhD trainee who is the first author on this paper upon the instance of the PARADIM user from NCSU who leads this project.

The work was initiated via a user proposal by Prof. Kaveh Ahadi from the North Carolina State University and includes a researcher from Clark Atlanta University (CAU), who performed the SIMS measurements, plus members of the PARADIM In-House Research Team facilitated through the DMR Partnerships for Research and Education in Materials Research (PREM): Emergent Interface Materials, granted to CAU, a PARADIM Trainee, and a PARADIM REU student.

T. Schwaigert, S. Salmani-Razaie, M.R. Barone, H. Paik, E. Ray, M.D. Williams, D.A. Muller, D.G. Schlom, and K. Ahadi, "Molecular Beam Epitaxy of KTaO3," J. Vac. Science & Technol. A 41, 022703 (2023).

Data Availability: Raw data collected during thin film growth are available via the PARADIM Data Collective at DOI: https://doi.org/10.34863/crr6-z966

This work made use of the synthesis and electron microscopy facilities of the Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM), which are supported by the National Science Foundation under Cooperative Agreement No. DMR-2039380. M.D.W., D.A.M., and D.G.S acknowledge support from the National Science Foundation (NSF) under No. DMR-2122147. This work made use of the Cornell Center for Materials Research (CCMR) Shared Facilities, which are supported through the NSF MRSEC Program No. DMR-1719875. This work made use of a Helios FIB supported by NSF (Grant No. DMR-1539918) and the Cornell Center for Materials Research (CCMR) Shared Facilities, which are supported through the NSF MRSEC Program (Grant No. DMR-1719875). K.A. acknowledges conversation with Zlatko Sitar. The authors acknowledge Steve Button for substrate preparation. The authors gratefully acknowledge Nicholas A. Parker and Yilin Evan Li for help with the AFM experiment, Sankalpa Hazra and Tatiana Kuznetsova for growing the sample used for SIMS experiment, and Dasol Yoon and Xiyue Zhang for providing EDX analysis code. M.D.W. also acknowledges NSD HRD1924204.