PARADIM Highlight #85—External User Project (2023)

Julia A. Mundy (Harvard), Antia S. Botana (Arizona State University), Ismail El Baggari (Harvard), Lena F. Kourkoutis (Cornell)

The nickelate superconductors were inspired by the cuprate superconductors, which remain today’s highest temperature superconductors at atmospheric pressure. Theorists have suggested straining the nickelate superconductors to enhance their superconducting properties and also assess how they differ from the cuprate superconductors. Importantly, strain can also introduce defects. It can be challenging to disentangle the effects of strain vs. defects. Here, a team of PARADIM users from Harvard and Arizona State Universities investigates the role of epitaxial strain in the competing requirements for the synthesis of the n = 3 Ruddlesden-Popper compound, Nd4Ni3O10, and subsequent reduction to the square-planar phase, Nd4Ni3O8.

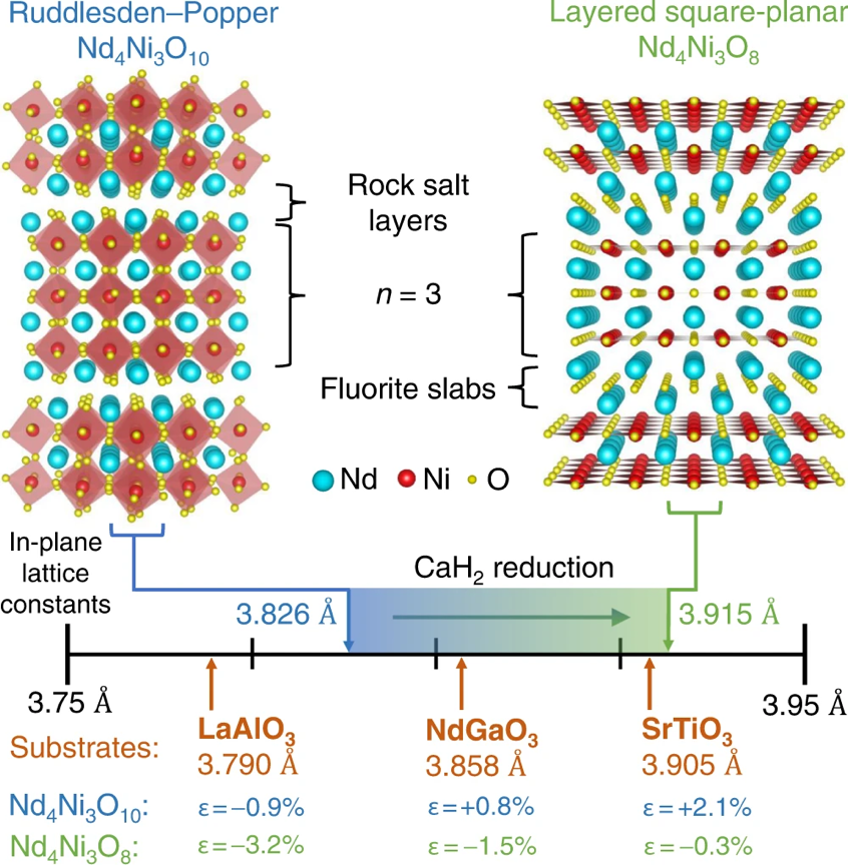

Figure 1: The nickelate superconductor Nd4Ni3O8 is metastable and synthesized by removing oxygen from the stable parent phase Nd4Ni3O10 at low temperature, where kinetics prevents decomposition. The number line shows the lattice parameters of Nd4Ni3O10, Nd4Ni3O8, and the substrates upon which Nd4Ni3O10 can be grown. Strain arises from growth as well as the Nd4Ni3O10 → Nd4Ni3O8 transformation. The mismatch between Nd4Ni3O10, Nd4Ni3O8, and the substrates are shown.

Using PARADIM’s signature MBE system they synthesize highest quality Nd4Ni3O10 films under compressive strain on LaAlO3 (001), while Nd4Ni3O10 on NdGaO3 (110) exhibits tensile strain-induced rock salt faults but retains bulk-like transport properties. A high density of extended defects forms in Nd4Ni3O10 on SrTiO3 (001). Films reduced on LaAlO3 become insulating and form compressive strain-induced c-axis canting defects, while Nd4Ni3O8 films on NdGaO3 are metallic. This work provides a pathway to the synthesis of Ndn+1NinO2n+2 thin films and sets limits on the ability to strain engineer these compounds via epitaxy.

The layered square-planar nickelates, Ndn+1NinO2n+2, are an appealing system to tune the electronic properties of square-planar nickelates via dimensionality; indeed, superconductivity was recently observed in Nd6Ni5O12 thin films. Here, we investigate the role of epitaxial strain in the competing requirements for the synthesis of the n = 3 Ruddlesden-Popper compound, Nd4Ni3O10, and subsequent reduction to the square-planar phase, Nd4Ni3O8. We synthesize our highest quality Nd4Ni3O10 films under compressive strain on LaAlO3 (001), while Nd4Ni3O10 on NdGaO3 (110) exhibits tensile strain-induced rock salt faults but retains bulk-like transport properties. A high density of extended defects forms in Nd4Ni3O10 on SrTiO3 (001). Films reduced on LaAlO3 become insulating and form compressive strain-induced c-axis canting defects, while Nd4Ni3O8 films on NdGaO3 are metallic. This work provides a pathway to the synthesis of Ndn+1NinO2n+2 thin films and sets limits on the ability to strain engineer these compounds via epitaxy.

We demonstrate a method to synthesize superconducting layered square-planar nickelate thin films and set limits on the ability to strain these compounds via epitaxy.

This work made use of PARADIM’s signature 62-element molecular-beam epitaxy system including its ability to provide an oxidant with high activity (distilled ozone) needed to achieve the Ni3+ in the as-grown films. PARADIM’s differentially pumped sources proved critical for this purpose as the extra pumping provided at the MBE sources allows 10 times higher pressures of distilled ozone to be employed at the substate during growth than standard MBE sources can withstand. This work also made use of PARADIM’s new ThermoFisher Spectra 300 X-CFEG electron microscope. PARADIM’s Theory and Simulation Facility contributed to advanced ab initio calculations.

The work is based on a collaboration among independent PARADIM users from Harvard University and Arizona State University, with contributions from PARADIM’s In-House Research Team, and independent researchers from Harvard University.

D.F. Segedin, B.H. Goodge, G.A. Pan, Q. Song, H. LaBollita, M.-C. Jung, H. El-Sherif, S. Doyle, A. Turkiewicz, N.K. Taylor, J.A. Mason, A.T. N'Diaye, H. Paik, I. El Baggari, A.S. Botana, L.F. Kourkoutis, C.M. Brooks, and J.A. Mundy, "Limits to the strain engineering of layered square-planar nickelate thin films," Nat. Commun. 14, 1468 (2023). DOI: 10.1038/s41467-023-37117-4

D.F.S. and B.H.G. contributed equally to this work. We thank Jennifer E. Hoffman and Michael Hayward for fruitful discussions. We thank H. Hijazi at the Rutgers University Laboratory of Surface Modification for assistance in Rutherford backscattering spectrometry. This project was primarily supported by the US Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering, under Award No. DE-SC0021925. Materials growth and electron microscopy were supported in part by the Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM) under NSF Cooperative Agreement No. DMR-2039380. Electron microscopy was primarily performed at the Cornell Center for Materials Research (CCMR) Shared Facilities, which are supported by the NSF MRSEC Program (No. DMR-1719875). Additional electron microscopy was performed using the MIT.nano facilities at the Massachusetts Institute of Technology and at Harvard University’s Center for Nanoscale Systems (CNS), a member of the National Nanotechnology Coordinated Infrastructure Network (NNCI), supported by the NSF division of Electrical, Communications and Cyber Systems (ECCS) under NSF Grant No. 2025158. This work made use of the Advanced Light Source, a U.S. DOE Office of Science User Facility under contract No. DE-AC02-05CH11231. D.F.S. acknowledges support from the US Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering, under award no. DE-SC0021925 and from the NSF Graduate Research Fellowship no. DGE-1745303. B.H.G. and L.F.K acknowledge support from PARADIM and the Packard Foundation. G.A.P. acknowledges support from the Paul & Daisy Soros Fellowship for New Americans and from the NSF Graduate Research Fellowship Grant No. DGE-1745303. Q.S. was supported by the STC Center for Integrated Quantum Materials, NSF Grant No. DMR-1231319. H.E.S. and I.E. were supported by the Rowland Institute at Harvard. J. A. Mason acknowledges support from the Arnold and Mabel Beckman Foundation through a Beckman Young Investigator grant. H.L. and A.S.B. acknowledge support from NSF Grant No. DMR 2045826. J.A. Mundy acknowledges support from the Packard Foundation and the Gordon and Betty Moore Foundation’s EPiQS Initiative, grant GBMF6760.