Introduction:

Boron carbide (B4C) is an extremely hard material with a melting temperature above 2000°C; its electronic properties vary strongly with the precise composition.

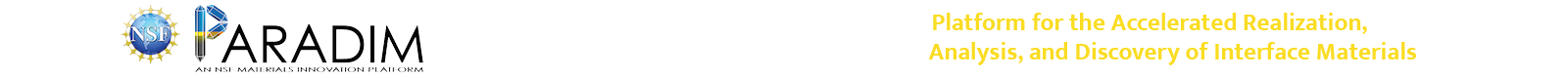

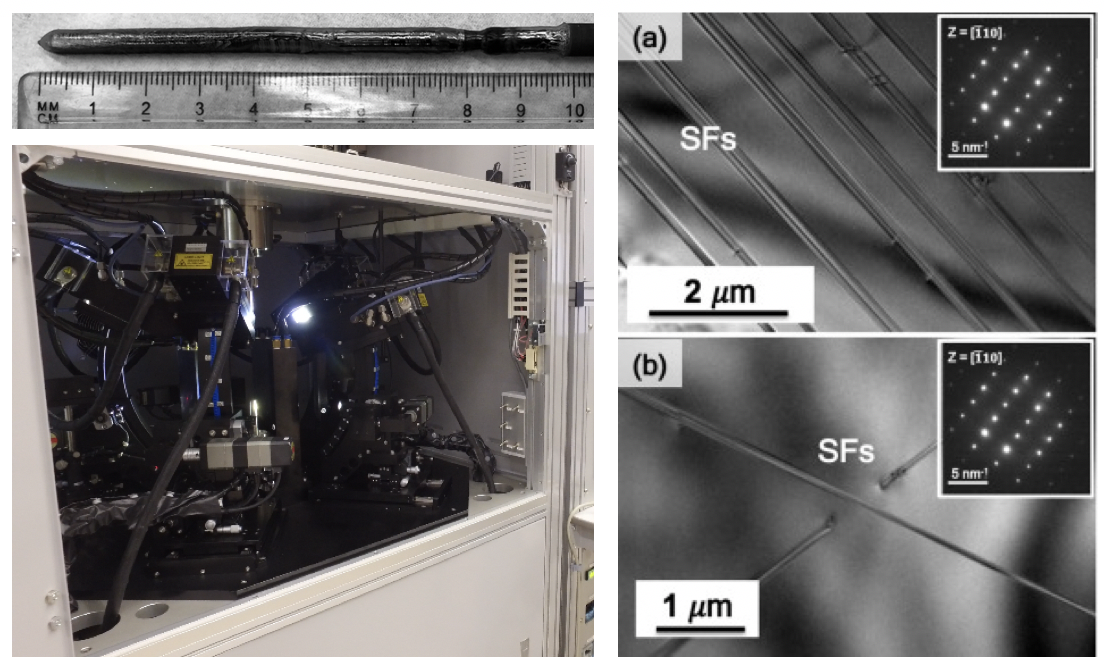

PARADIM’s Tilting Laser Diode Floating Zone Furnace enables users to routinely grow B4C single crystals for further study. The in-situ monitoring of gas-phase species during the growth provides insights on the underlying mechanism by which the composition changes and enables the successful growth of single crystals with controlled stoichiometry. Various growth rates were explored to mitigate microstructure defects (including stacking faults, SF) and zone refinement allowed for a significant reduction of trace impurities. Initial analysis by powder x-ray diffraction confirms that the crystals are indeed rhombohedral B4C, with a hardness of 41±1 GPa and a Young’s modulus of 520±14 GPa revealed by nano-indentation. Laser light was found to induce graphitization in the presence of air, enabling a new process to fabricate electronic structures in boron carbide with micron or nanoscale precision.

M. Straker et al. J. Cryst. Growth 543, 125700 (2020).

M.V.S. Chandrashekhar et al., U.S. Patent No. US20190352234-A1 (21 November 2019).

Technical details: We report the growth of 4 mm diameter × 50 mm long Boron Carbide (B4C) with large single crystal regions using a Laser Diode Floating Zone (LDFZ) method at varying growth rates of 5–20 mm/hr. These materials were grown using polycrystalline B4C as a seed. Microstructural characterization shows the presence of a significant number of twinning-boundaries along the growth direction ([0 0 1]h) oriented in the (1210)h plane. At faster growth rates >10 mm/hr, the crystal orientation was reproducible, suggesting a twin-plane mediated growth mechanism. On the contrary, at slower growth rates <10 mm/hr the crystal orientation was not reproducible, suggesting a critical rate for twin-plane mediated growth to dominate.

Zone refinement of these crystals led to a significant reduction of trace impurities to better than 99.999 wt% purity, at the expense of increased twinning. Powder x-ray diffraction confirms that the bulk is rhombohedral B4C, consistent with the microstructural analysis. The X-ray reciprocal space maps reveal the growth direction to be close to the [001]hdirection, and the corresponding ω-rocking curve width is ~530 arcsec. The rocking curve consisted of 3 distinct peaks, indicating in-plane mosaicism, consistent with the twinning observed. Berkovich nano-indentation of the key (001)h plane showed 41 ± 1 GPa hardness, with a Young’s modulus of 520 ± 14 GPa, comparable to literature reports. In addition, it was discovered that the laser field could induce graphitization of boron carbide in air, a new, previously unknown phenomena that led to a patent application due to the potential uses of the technique in fabricating electronic structures in single crystal boron carbide substrates.

Researchers of Morgan State University initialized and performed the work at the PARADIM Bulk Crystal Growth Facility located at John Hopkins University.

Full references:

Michael Straker, Ankur Chauhan, Mekhola Sinha, W. Adam Phelan, M.V.S. Chandrashekhar, Kevin J. Hemker, Christopher Marvel, and Michael Spencer, “Growth of high purity zone-refined Boron Carbide single crystals by Laser Diode Floating Zone method,” J. Cryst. Growth 543, 125700 (2020).

M.V.S. Chandrashekhar, Joshua Letton, Travis Williams, Abdulganiyu Ajilore, and Michael Spencer “Laser Induced Graphitization of Boron Carbide in Air,” U.S. Patent No. US20190352234-A1 (21 November 2019) https://patents.google.com/patent/US20190352234A1/en.