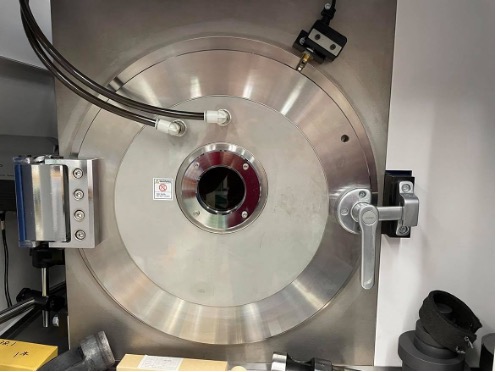

Spark Plasma Sintering

Spark plasma sintering (SPS), also known as field assisted sintering technique or pulsed electric current sintering, or Plasma Pressure Compaction, is a sintering technique in which powdered sample can be sintered under uniaxial pressure.

The SPS at PARADIM is capable of operating at a temperature of 2500 °C with an option to provide Argon gas flow or vacuum. The applied Force can be varied between 1-60 kN. In an SPS, Joule heating plays a dominant role in the densification of powder compacts, which results in achieving near theoretical density at lower sintering temperature compared to conventional sintering techniques, enabling retaining of micro and nanostructures.

At PARADIM, the SPS is often used to make homogeneous targets of novel electronic materials for thin film growths, such as the material shown here.

Sample Publications Using this Instrument

J. Xu, W.A. Phelan, and C.L. Chien, “Large Anomalous Nernst Effect in a van der Waals Ferromagnet Fe3GeTe2," Nano Lett. 19, 8250 - 8254 (2019).