PARADIM Highlight #103—MIP Collaboration (2025)

Fangxi Wang, Abhishek T. Sose, and Sanket A. Deshmukh* (GlycoMIP) and Allana G. Iwanicki, Lucas A. Pressley, and Tyrel M. McQueen* (PARADIM)

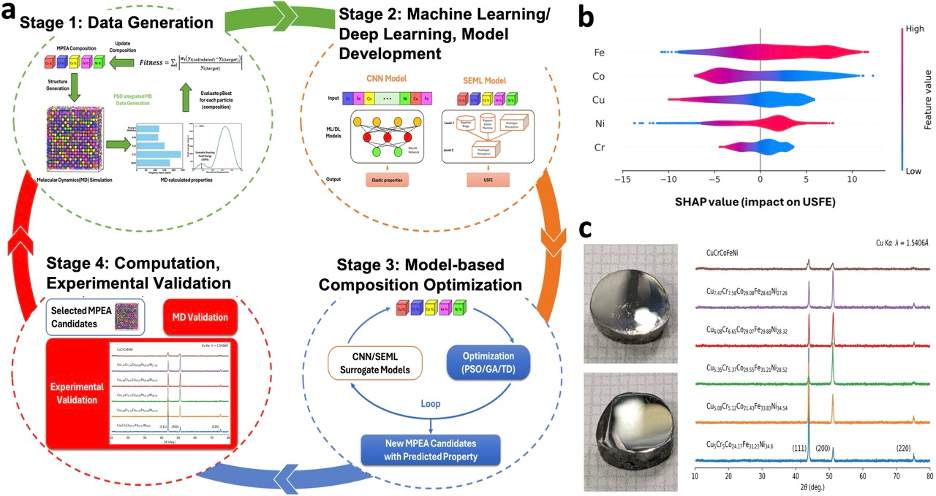

This project developed an integrated computational workflow that combines a stacked ensemble machine learning (SEML) model, a convolutional neural network (CNN) model, and evolutionary algorithms to design advanced FeNiCrCoCu multi-principal element alloys (MPEAs) with enhanced mechanical properties. Candidate MPEA compositions predicted through this approach were synthesized and experimentally validated, indicating single-phase face-centered cubic (FCC) structures with mechanical properties (hardness and Young’s modulus) qualitatively agreed with the computational predictions. SHapley Additive exPlanations (SHAP) analysis provided valuable insights into the computational models, revealing the relationship between elemental concentrations and unstable stacking fault energies in the SEML model, and highlighting correlations between local elemental clustering and mechanical properties in the CNN model. Currently, the workflow from this project is further modified and is being employed to accelerate the design of glycomaterials.

Figure 1: (a) Flowchart of the four-stage hybrid computational workflow. (b) SHAP analysis of the SEML model for the prediction of unstable stacking fault energy (USFE), revealing the influence of elemental concentrations on the USFE. (c) Experimentally synthesized MPEAs, which showed qualitative agreement with computational predictions.

The GlycoMIP supported this research by leading the development of a computational workflow and framework to accelerate materials design. PARADIM synthesized the new MPEAs and characterized their mechanical properties.

A team of researchers, led by Sanket Deshmukh at Virginia Tech (GlycoMIP), developed a computational workflow machine learning and deep learning models with evolutionary algorithms to identify new compositions of FeNiCrCoCu multi-principal element alloys (MPEAs). A team led by Tyrel M. McQueen at JHU (PARADIM) synthesized and tested these compositions.

The integrated computational workflow, established in this study, enables new design strategies for MPEAs with enhanced properties. This workflow could be readily expanded the other materials systems.

The research was enabled by GlycoMIP’s unique expertise and capabilities to develop the computational workflow by integrating molecular dynamics simulations, machine learning and deep learning model development with PARADIMs capabilities to create new inorganic crystalline materials.

F. Wang, A.G. Iwanicki, A.T. Sose, L.A. Pressley, T.M. McQueen, and S.A. Deshmukh, "Experimentally Validated Inverse Design of FeNiCrCoCu MPEAs and Unlocking Key Insights with Explainable AI," npj Comput. Mater. 11, 124 (2025).

This work was supported by GlycoMIP, a National Science Foundation (NSF) Materials Innovation Platform (MIP) funded through Cooperative Agreement DMR-1933525. We also acknowledge the NSF-funded MIP, Platform for the Accelerated Realization, Analysis, and Discovery of Interface Materials (PARADIM) under Cooperative Agreement DMR-2039380. The authors would like to acknowledge Advanced Research Computing (ARC) at Virginia Tech for computational resources. This research also used resources of the National Energy Research Scientific Computing Center (NERSC), a scientific computing facility for the Office of Science in the United States Department of Energy, operated under Contract No. DE-AC02-05CH11231.

Data Availability: The simulation code, along with the generated datasets, and model training scripts, is available on a GitHub repository https://github.com/Deshmukh-Group/Code_For_XAI_MPEA.